A New Laboratory – Keeping Every Factor Under Control

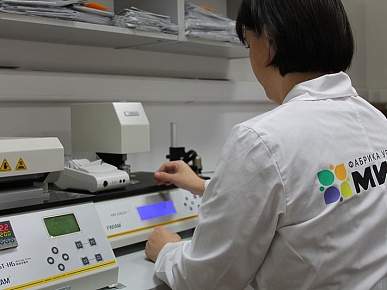

Our plant has launched a new laboratory. Several tens of thousands of euros were invested in the equipment system produced by an American-Chinese Labthink company. Testers and automated machines for measuring various raw material and final product indicators, examining relations between packages and surrounding environment and materials will allow us to conduct prompt quality check, and to improve the product according to different customer needs.

For example, diary producers have different opinions as to the optimal merit of the die-cut lid tear force – one of the main factors in the packaging process. Requirements vary from 5 to 12 n/m. A tension testing machine will allow us to control the level, fine-tune the equipment for particular customer needs, and to keep the indicators stable. The automated machine tests the product for breaking force, elongation at break, and the tearing force of sealed samples.

To improve the sealing quality, the laboratory was equipped with an automated sealer. The sealer works within a wide temperature range, with the accuracy of up to 0,1 degree, and the maximum pressure limit of 10 bar. The automated machine allows sealing samples with constant welding seam width, which guarantees equal testing conditions.

The laboratory is also equipped with an automated thickness tester, an air-tightness tester, and an attrition tester that checks the paint and lacquer coating for mechanical corruption resistance with an electronic microscope. This more thorough and detailed raw material and final product control goes in line with the requirements of the biggest dairy and pharma companies operating according to the European standards. This work will entail production optimization and will contribute to the increased customer satisfaction.